FlexSorter

Transplanting, gapping up and packing.

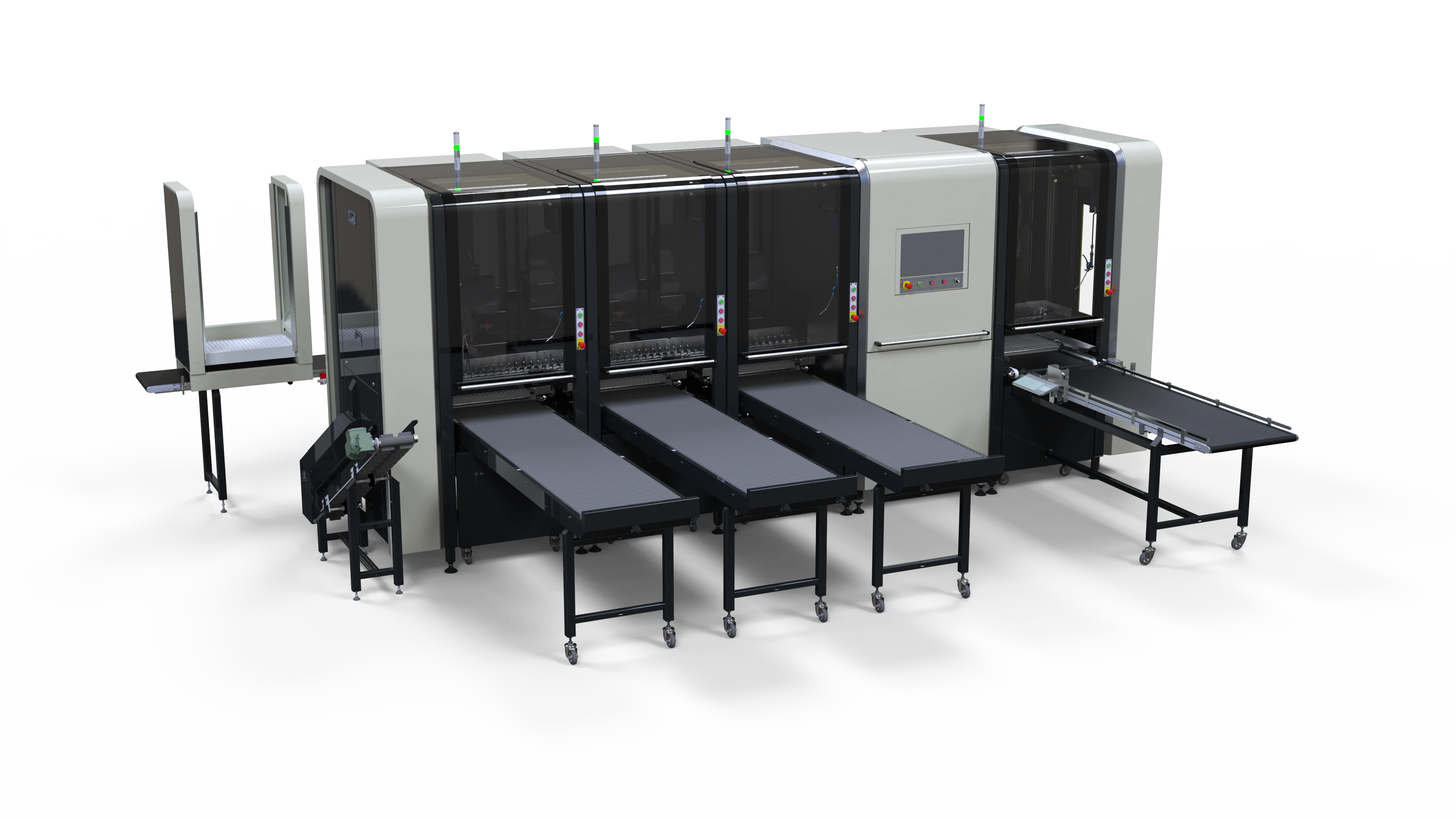

The FlexSorter is a unique selection equipment that combines transplanting and multiple class selection into one simple step.

Description

The FlexSorter extracts plants from the donor tray with our in-house developed plant grippers, assisted by a pusher pin system from below. The machine is unique since it selects plants and handles the plugs only once.

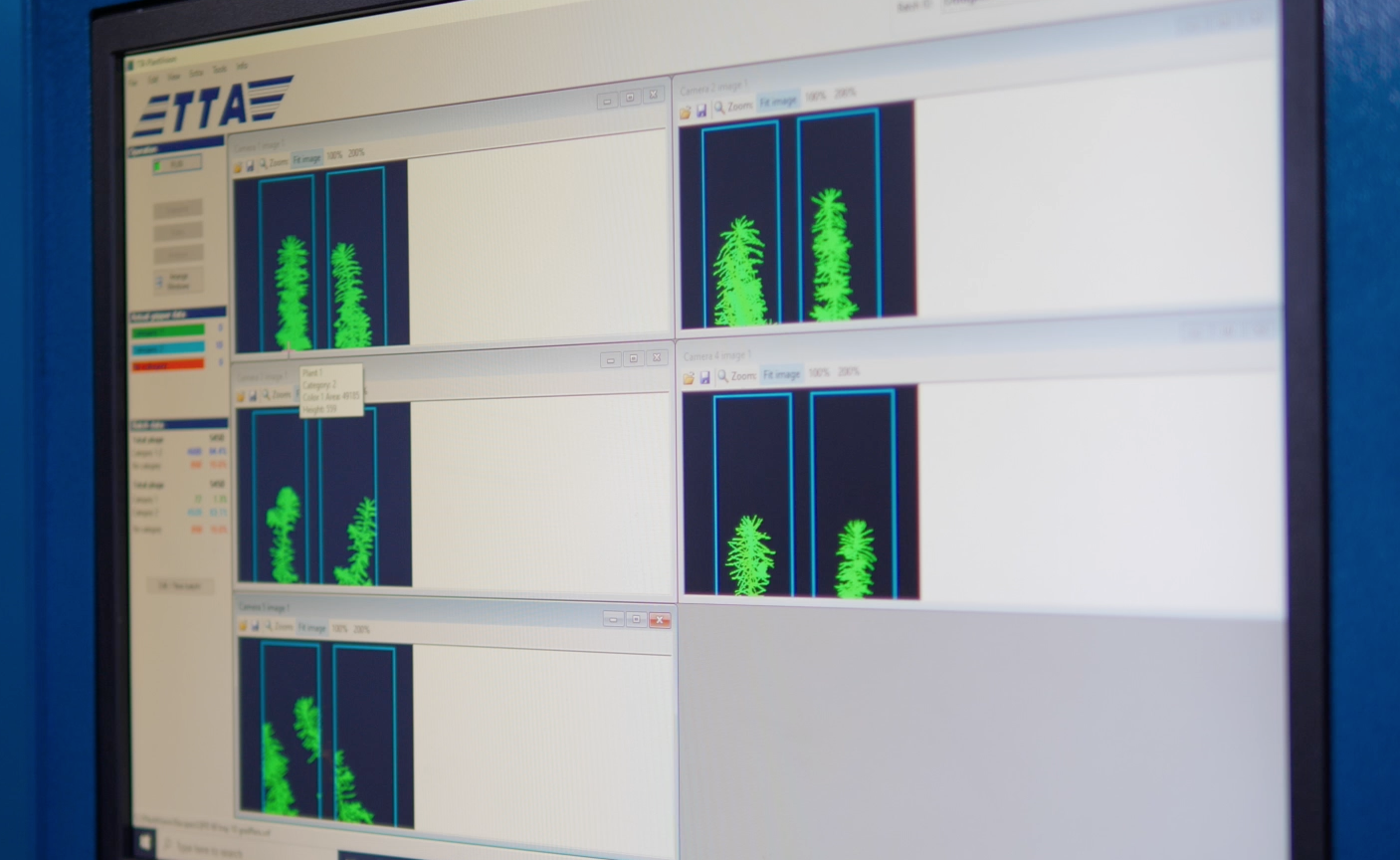

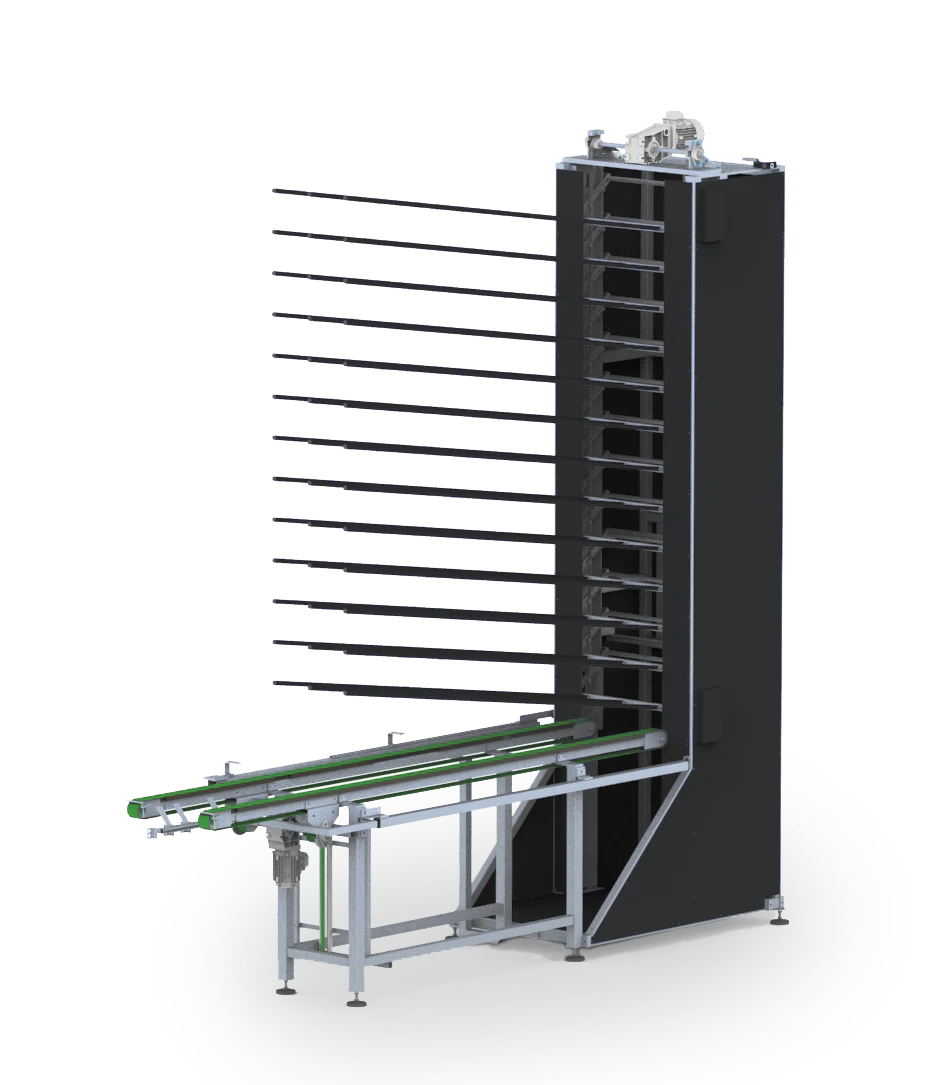

The plant grippers give the plants space so that it's easy to determine the plant's quality. After selection, the FlexSorter transfers approved plants to the selected destination belts, grade by grade. The number of classifications depends on the number of destination belts and is maximized at four.

Discarded plants and empty plugs are collected on a waste belt. The selected trays are all combined, class by class. Both the machine and the imaging system offer an easy-to-understand user interface with inbuilt self-diagnosis. The FlexSorter is the new generation of selection equipment, avoiding plant damage due to double handling of plants.

Specs

Operators

1

Plug diameter

9 - 60 mm

Capacity per hour

3.000 - 12.000 plugs

FlexSorter

in action

Ready to take your operations to the next level with cutting-edge automation? Let’s talk — we’re ready to help you grow beyond limits.