The future of tomato harvesting

Labor shortages and rising production demands have made automation essential in greenhouse horticulture. Yet, automated tomato harvesting has remained one of the industry’s greatest challenges—until now.

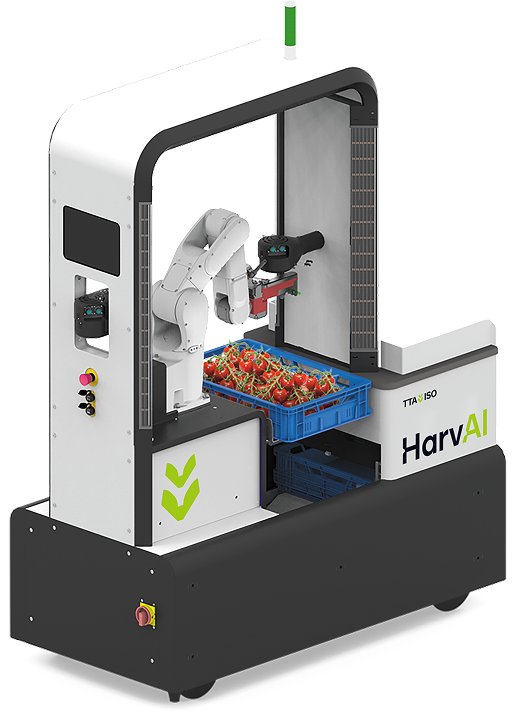

After years of research, development, and rigorous field testing, TTA-ISO proudly introduces HarvAI®, a groundbreaking harvesting robot engineered to deliver consistent, high-quality results at scale.

Rethink the way

you harvest tomatoes

HarvAI® integrates precise ripeness detection, intelligent navigation, and seamless compatibility with existing greenhouse infrastructure. With a cycle time of 450 vines per hour and the capability for one operator to oversee multiple robots, it maximizes efficiency while minimizing crop damage.

Designed for reliability and performance, this harvesting robot sets a new standard in automated tomato production.

01

Advanced AI algorithms

Precise ripeness detection and optimal picking.

02

Operational speed

With a cycle time of 450 vines per hour.

03

Seamless integration

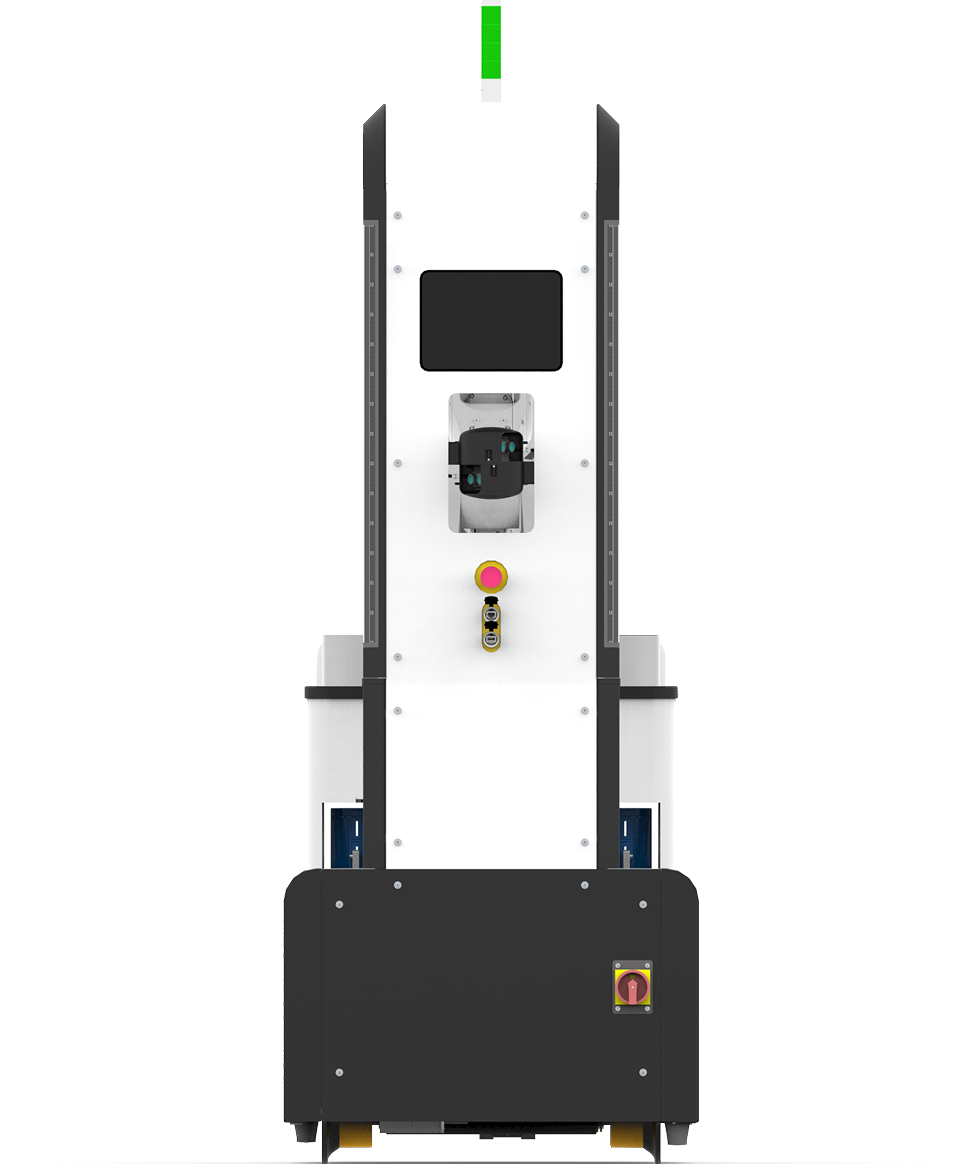

Drives on heating rails, with uniform dimensions 550-600 mm.

04

3D guided path

Smart robot navigation prevents damage and optimizes routes.

05

Scalable operation

1 operator controls up to 6 harvesting robots.

06

Temperatures

Operates in 10-40ºC and 75-90% RH.

Key benefits

Ready to take your operations to the next level with cutting-edge automation? Let’s talk — we’re ready to help you grow beyond limits.

View product page

Back to overview

Latest innovation

Breakthrough in automated tomato harvesting.