CuttingEdge Double

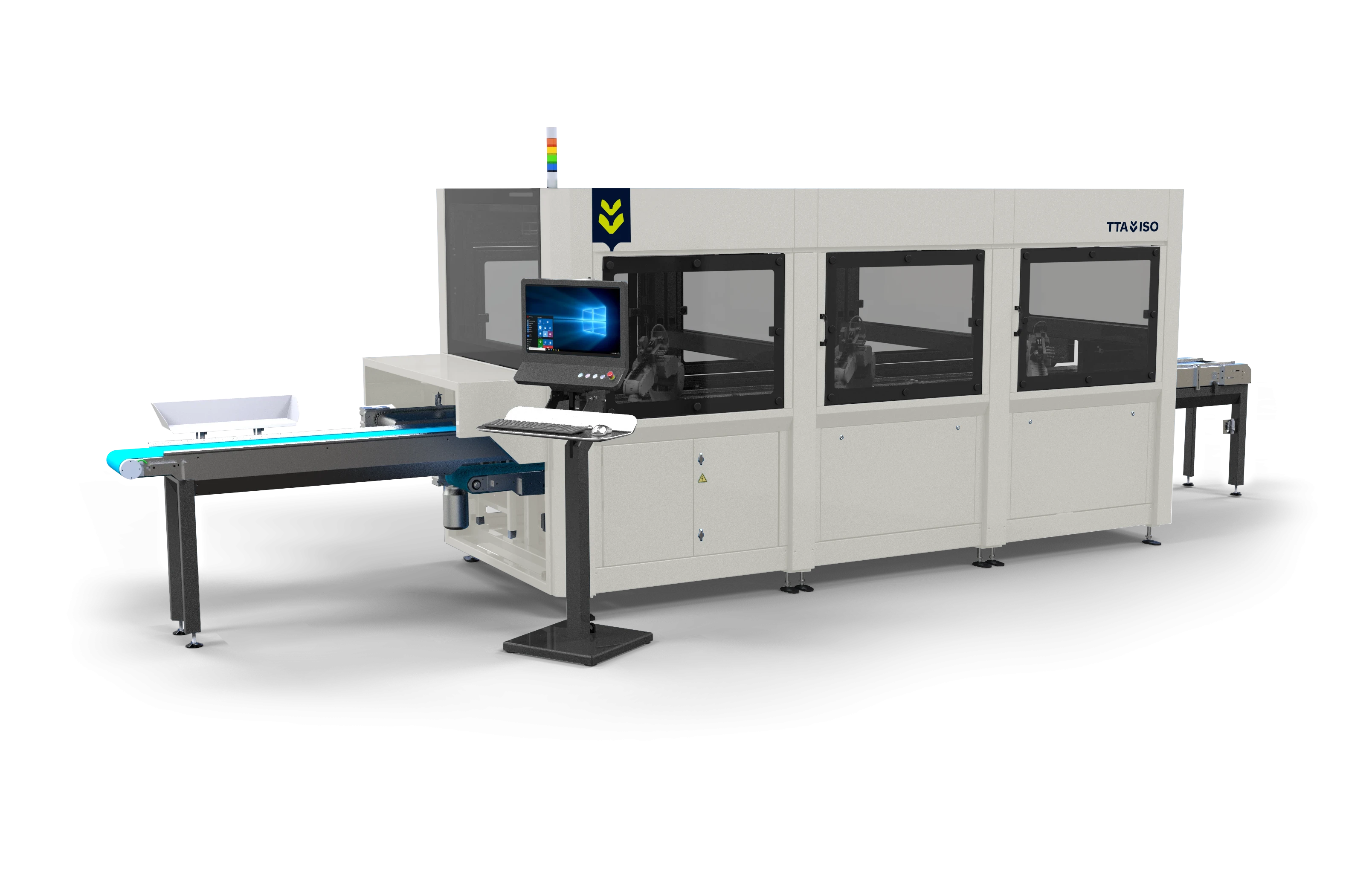

Double cutting planter with a capacity of 4.000 - 4.500 cuttings per hour.

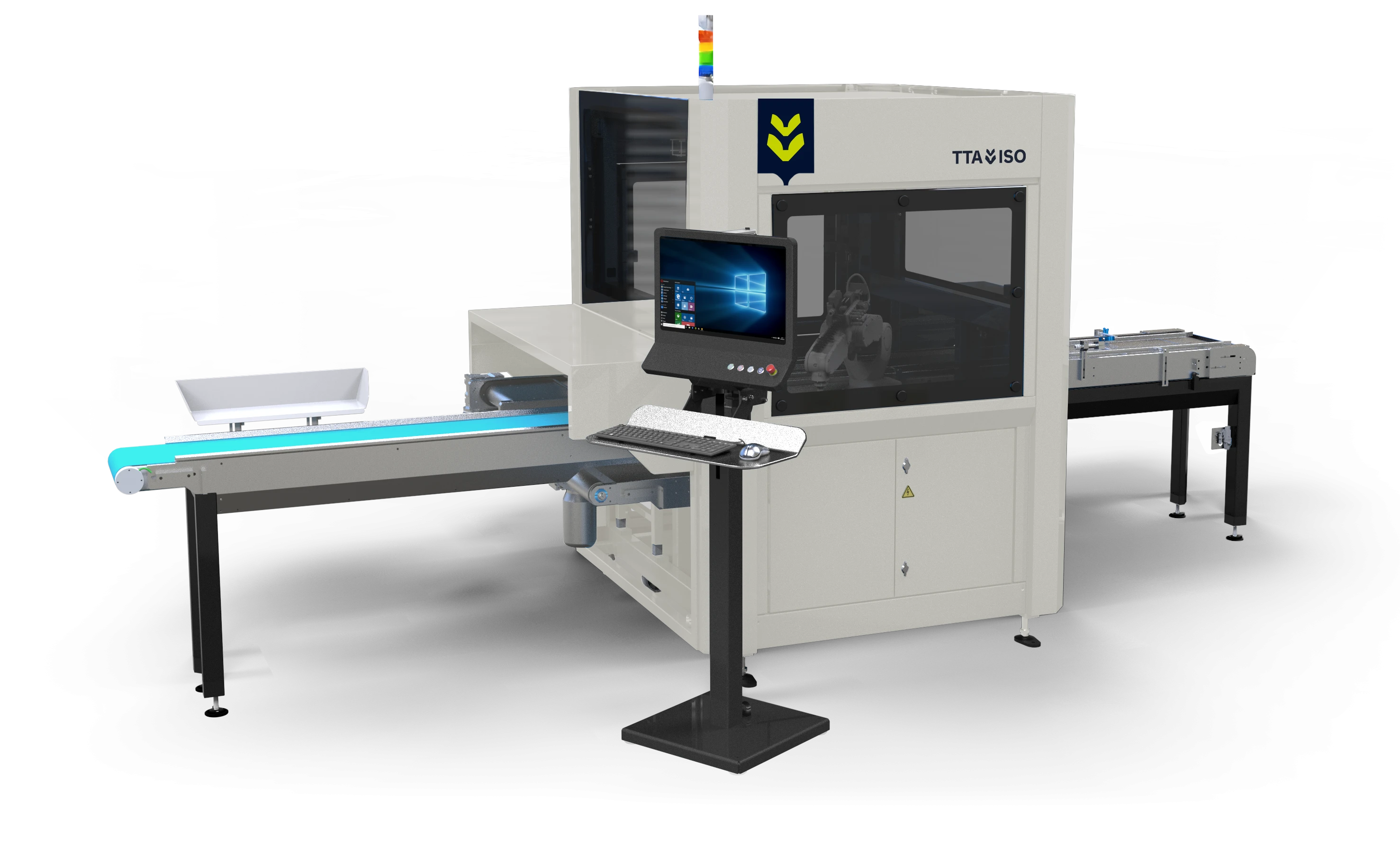

The CuttingEdge Double is an automated sticking machine for planting rooted and unrooted cuttings.

Description

The CuttingEdge is here to revolutionize your planting process, making it faster, smarter, and more efficient than ever before. The machine is engineered for accuracy and productivity, the CuttingEdge brings a new level of precision to your nursery operations.

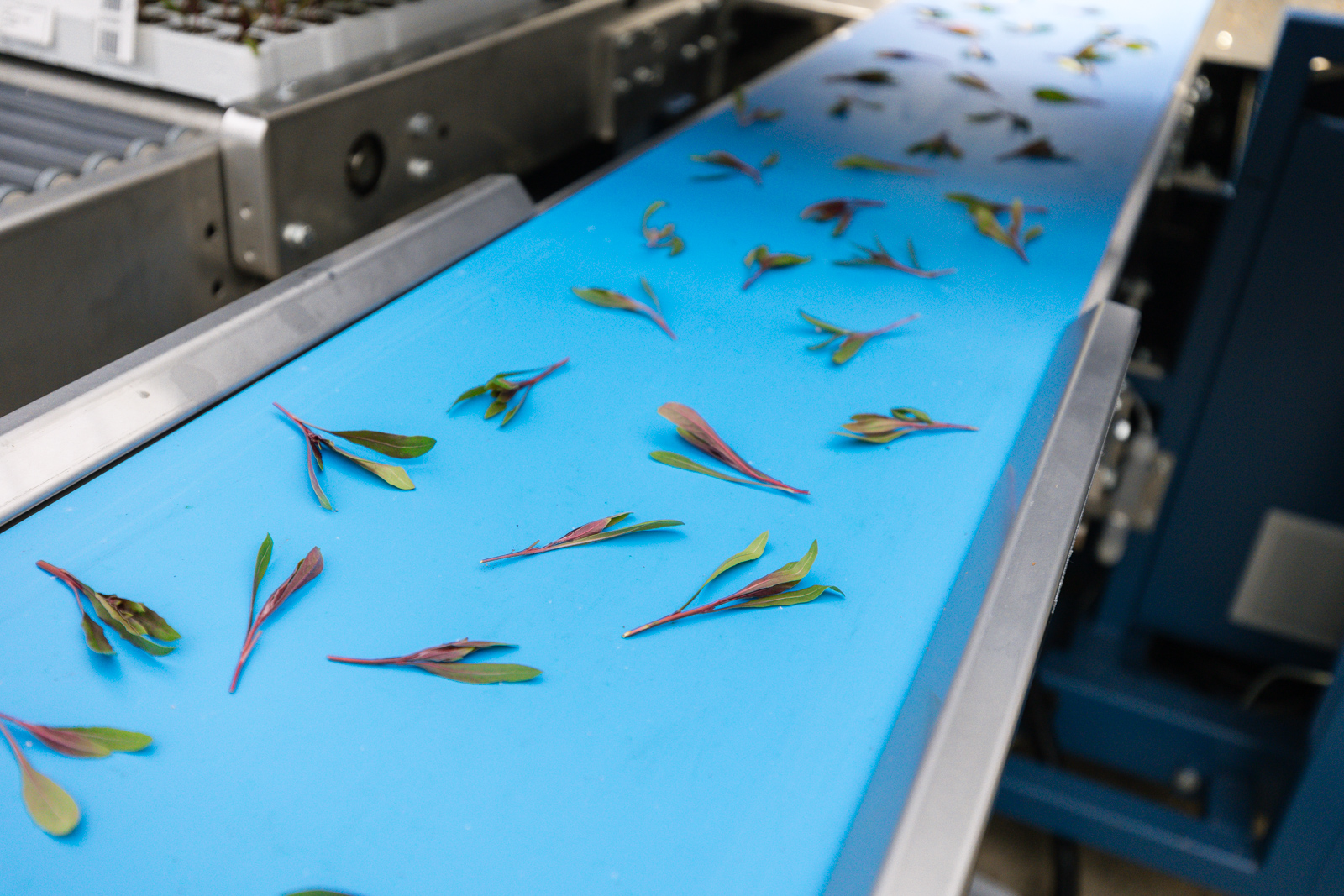

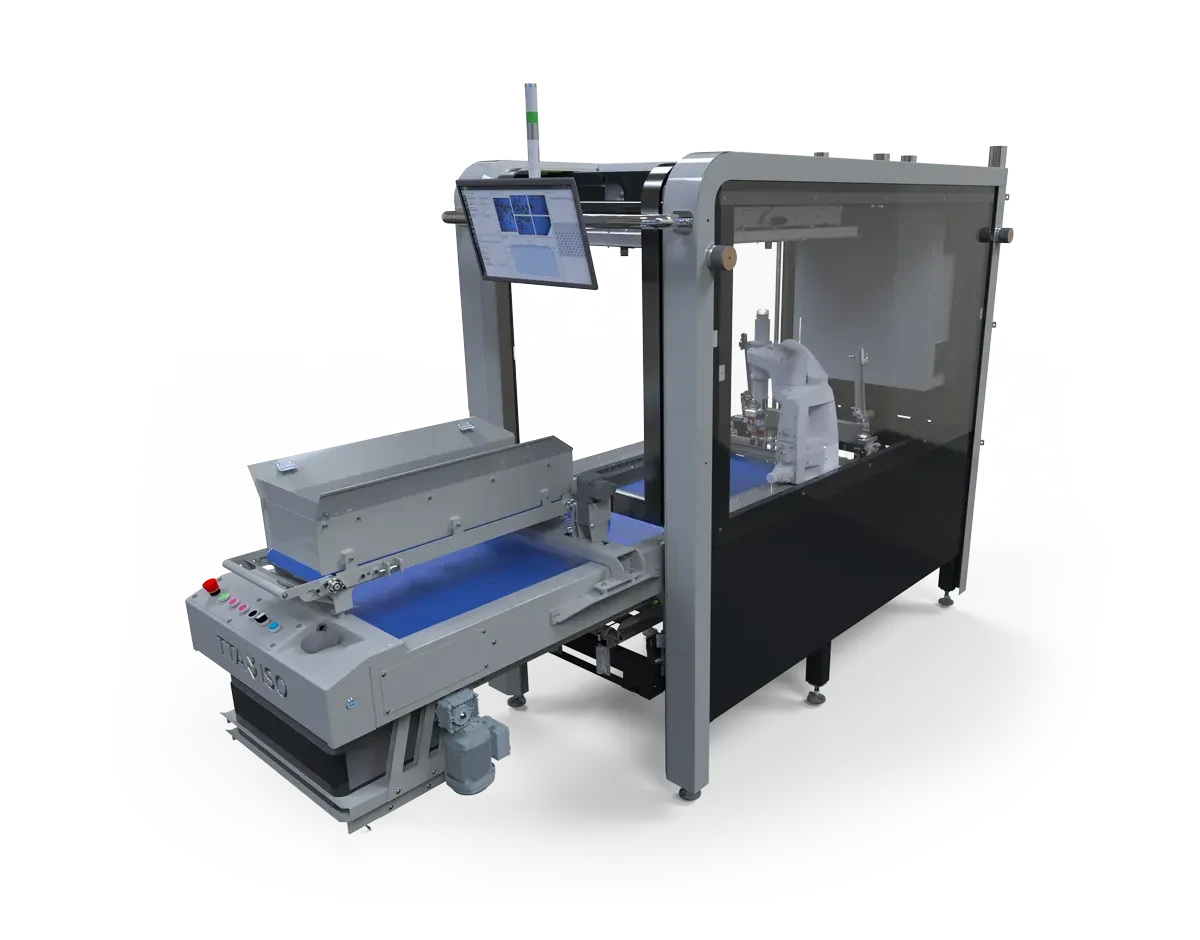

Plug trays are placed onto the in-feed chain conveyor, either manually or automatically. The chain conveyor then accurately positions the trays at their destination. Cuttings can be separated manually on the pick-up conveyor or automatically with VisionAir, which uses advanced vision technology and air jets to ensure only perfectly separated cuttings are delivered to the CuttingEdge.

The camera system assesses the cuttings with the TTA-ISO CuttingVision system. Then, only qualified cuttings are planted into the plug tray with the robotic arm. Rejected or duplicated cuttings are returned to the operator's position by a return system.

VisionHub by TTA-ISO

TTA-ISO is committed to bringing the automated sticking process to the highest possible level in cooperation with all users of CuttingEdge. To achieve this, all data created by teach-in and annotating for the cutting setups is collected in VisionHub. This data is available to all CuttingEdge users. This achieves the following:

Improvement of sticking setups, the more data, the more robust the setups become.

Time savings for users by using available cutting setups from VisionHub.

Specs

Capacity per hour

4.000 - 4.500 cuttings

CuttingEdge Double

in action

Ready to take your operations to the next level with cutting-edge automation? Let’s talk — we’re ready to help you grow beyond limits.