VisionAir

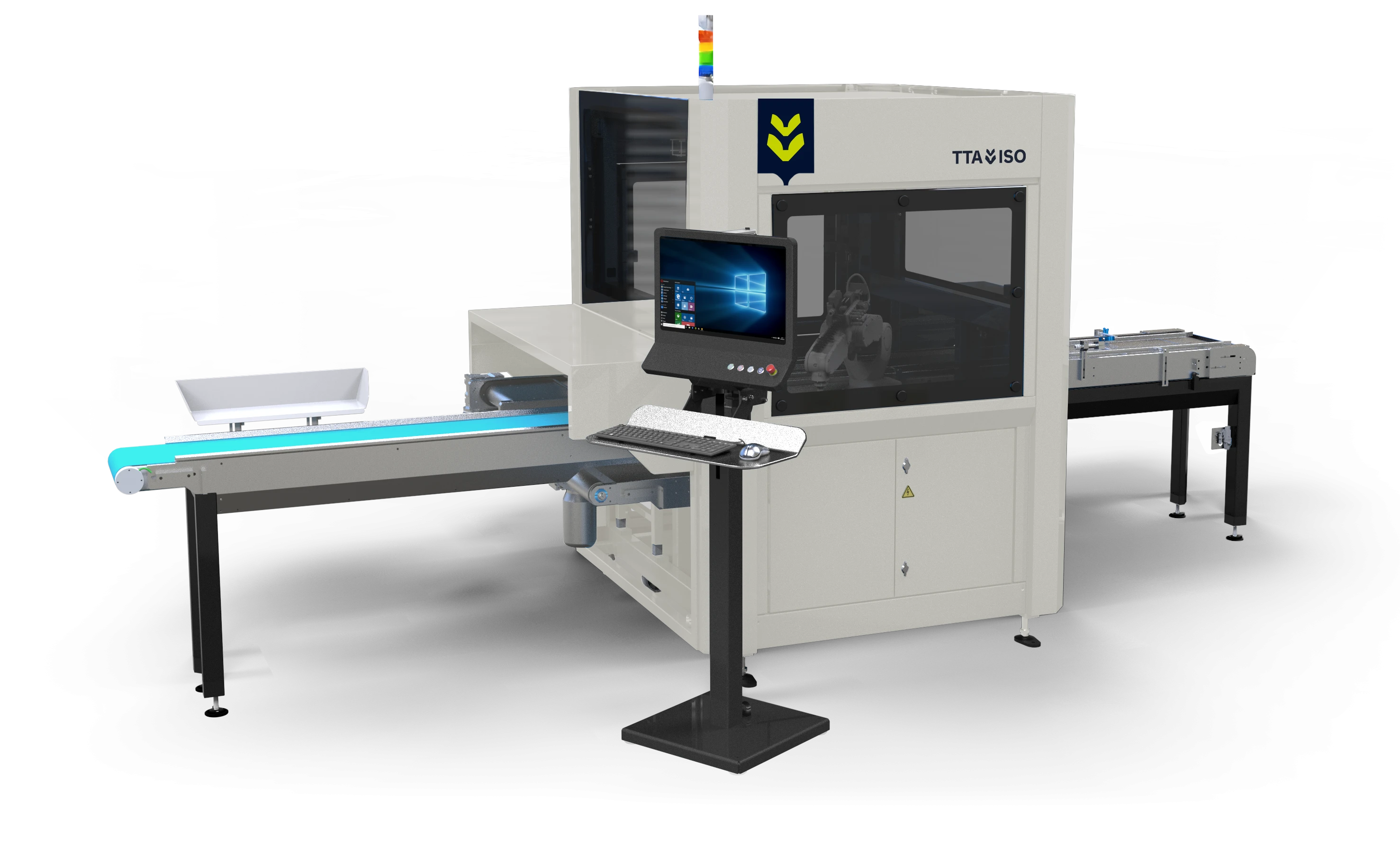

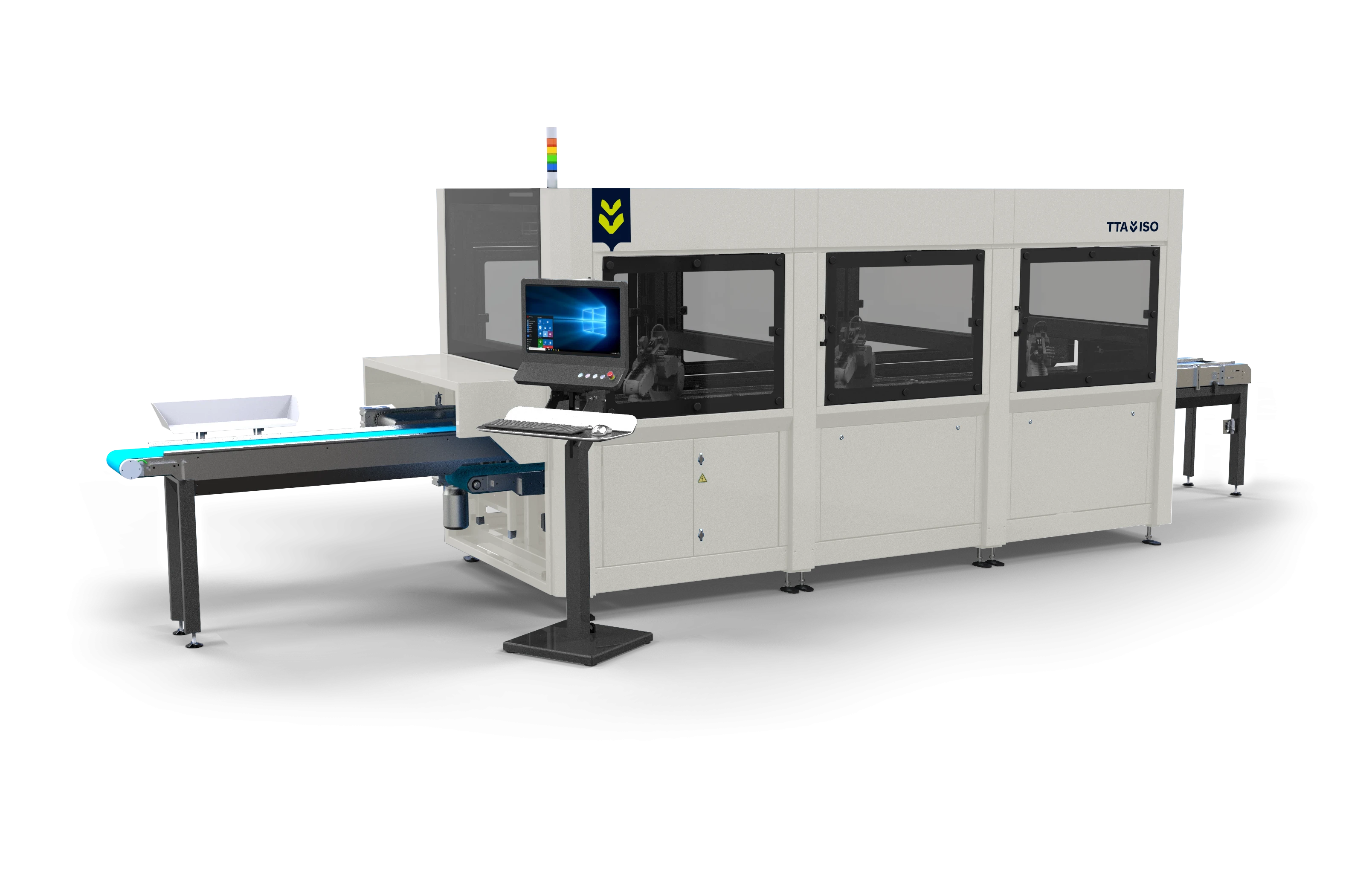

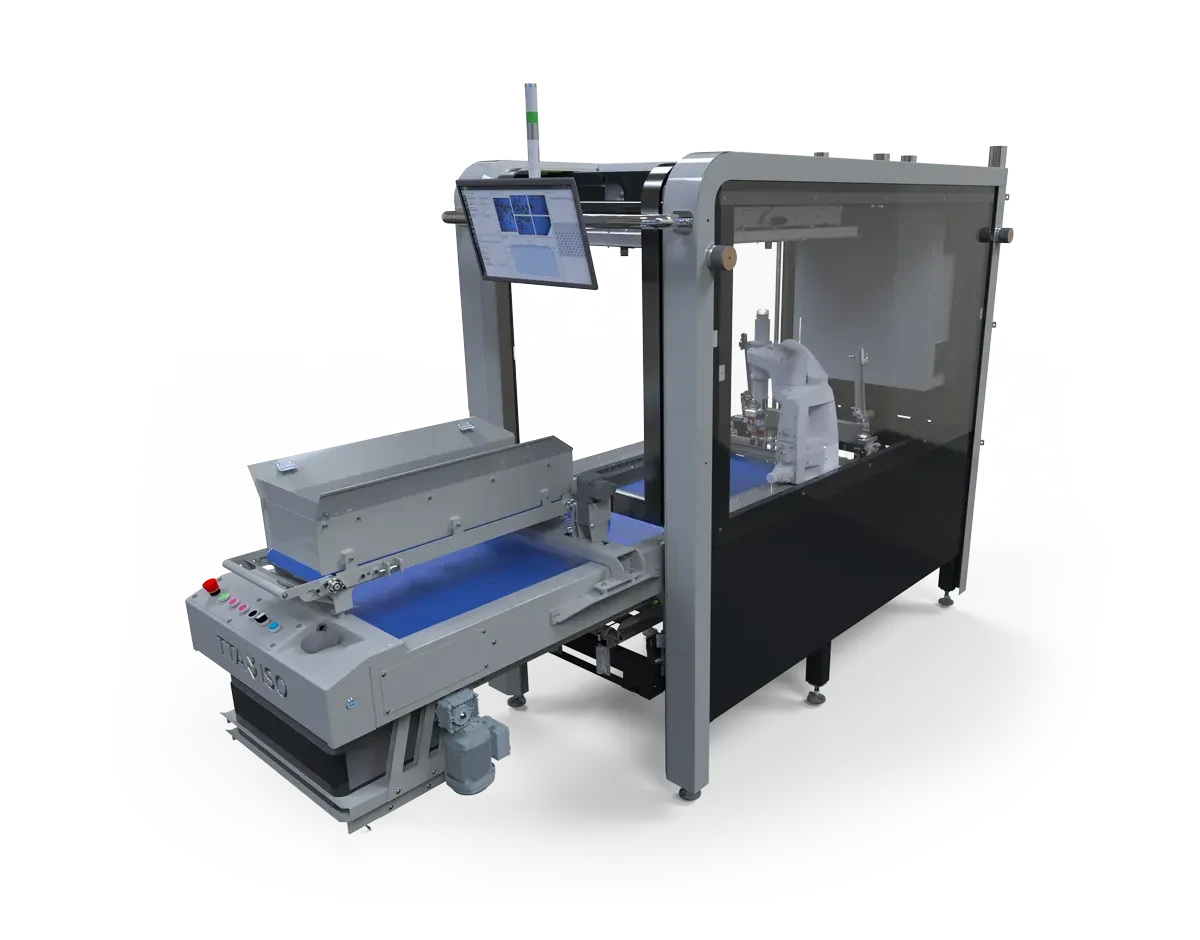

VisionAir uses advanced vision technology and precision air jets to separate plant cuttings automatically.

The VisionAir utilizes advanced vision technology and precision air jets to separate plant cuttings automatically.

Description

The VisionAir automatically separates plant cuttings using a jet of pressurized air to feed them individually into the CuttingEdge.

Cuttings are placed on the conveyor belt. When the camera detects that the mesh belt can receive new cuttings, the conveyor belt is activated. A heap of cuttings falls onto the mesh belt. The same camera detects whether the cuttings are separated or stacked on top of each other. Loose cuttings are passed through, while stacked cuttings are blown back by a nozzle. The row of nozzles only allows separated cuttings to pass through, which are finally delivered to the conveyor belt of the CuttingEdge machine.

VisionHub by TTA-ISO

TTA-ISO is committed to bringing the automated sticking process to the highest possible level in cooperation with all users of CuttingEdge. To achieve this, all data created by teach-in and annotating for the cutting setups is collected in VisionHub. This data is available to all CuttingEdge users. This achieves the following:

Improvement of sticking setups: The more data there is, the more robust the setups become.

Time savings for users by using available cutting setups from VisionHub.

Ready to take your operations to the next level with cutting-edge automation? Let’s talk — we’re ready to help you grow beyond limits.